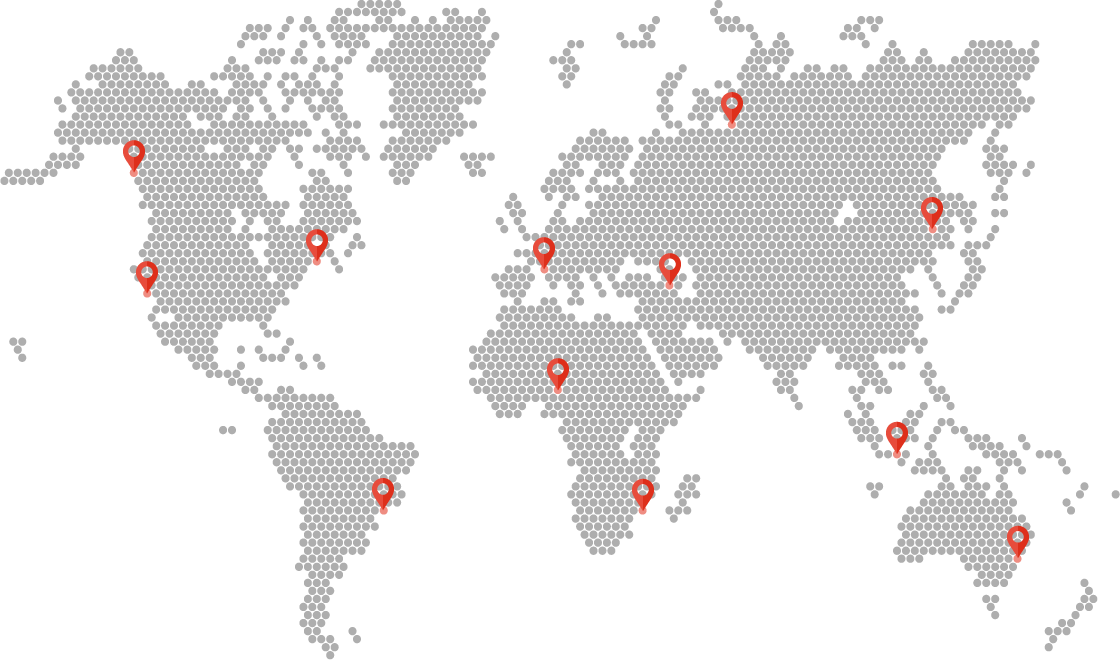

We serve over 500 renowned global brands and maintain long-term partnerships with more than 60 listed companies.

Our products are widely applied in consumer electronics, automotive, new energy, medical, and other sectors, trusted by leading industry players.

Group photo with customers

Customer Stories

Why Choose Us

Customer Stories

Exhibition or project case

Who We Are

Engineering Case: Technical Research on Buck-Boost Inductors and Customer Demand Response Practice

Project Background and Challenges

Customer Requirements

A smart sprayer manufacturer (project code YQ0017) required a custom high-frequency inductor component that met the technical specifications of dual inductances of 30μH/600μH and current loads of 0.3A/1.5A for use in a buck-boost circuit module.

The initial proposal (CD0805-25/800μH) was rejected due to overheating and insufficient current draw, and a 3% defect rate occurred during the pilot production phase (due to external forces causing copper wire shorts).

Technical Difficulties

1. Size constraints; how to balance inductance accuracy and heat dissipation performance within a miniaturized design.

2. Improved copper wire resistance to mechanical damage and stability.

Problem analysis and solution path

Phase 1: Parameter Optimization (September-November 2024)

Root Cause Analysis: The original inductor core material was unstable, and its saturation characteristics were not suitable for high-frequency operating conditions.

Solution Iteration: Adjusting the winding process increased the inductance of pins 1-2 from 25μH to 30μH.

Using a layered winding method to reduce eddy current losses in pins 1-3, increasing current carrying capacity by 15%.

Phase 2: Reliability Upgrade (January 2025)

Innovative Design:

Developing a new YPRH0704C-300M:601M structure, using a shielding cover + epoxy resin potting + dual protection to address copper wire wear.

Key Achievements and Benefits

1. Technical Targets Achieved Target: Industry Standard Project Outcome Defect Rate: ≤1% Response Speed: 7 days 72 hours Customer Repurchase Rate: 11 additional orders Business Value 1. Helped the client complete 618 inventory preparations on schedule, with cumulative deliveries reaching 48,000 units 2. Allowed the client to witness Shenzhen’s speed

Lessons Learned

Agile Development: From problem feedback to prototype verification within 72 hours Interdisciplinary Collaboration: Structural engineers and materials experts collaborate on copper wire protection solutions Customer-Oriented Thinking: Achieving a closed “design-manufacturing-feedback” loop through pilot production and follow-up