Features

● High density packaging with a pitch of 2.54mm(0.1 inch) max. is possible.

This series requires less space and has greater EMI suppression effects.

● Different types with the same shape are available.

● Excellent in physical properties,such as terminal strength,flexure strength,

soldering resistance and soderability.

● Applicable to both flow and reflow soldering.

● High impedance cover wide frequency ranges.

● Operating temperature:-40℃ ~ +125℃(Including self-temperature).

Applications

● Computers and peripheral devices,personal computers,VCR and cameras.

● Noise suppression in digital equipments,car stereo,car engines controllers

and OA electronic instruments.

● Communication equipment.

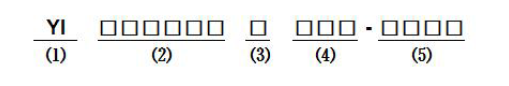

1 Product Identi fication

⑴ :Type

⑵ :Dimensions

⑶ :Material Code

⑷ :Impedance

⑸ :Rated Current

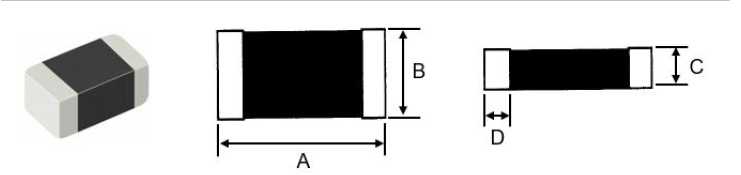

2 Shapes and Dimensions(Unit:mm)

| TYPE | A | B | C | D |

|---|---|---|---|---|

| YI100505 | 1.00±0.15 | 0.50±0.15 | 0.50±0.15 | 0.25±0.15 |

| YI160808 | 1.60±0.20 | 0.80±0.20 | 0.80±0.20 | 0.30±0.20 |

| YI201209 | 2.00±0.20 | 1.20±0.20 | 0.90±0.20 | 0.50±0.30 |

| YI321609 | 3.20±0.20 | 1.60±0.20 | 0.90±0.20 | 0.50±0.30 |

| YI322513 | 3.2±0.20 | 2.5±0.20 | 1.3±0.20 | 0.5±0.3 |

| YI451616 | 4.5±0.20 | 1.6±0.20 | 1.6±0.20 | 0.5±0.3 |

| YI453215 | 4.5±0.20 | 3.2±0.20 | 1.5±0.20 | 0.5±0.3 |

| YI565030 | 5.59±0.20 | 5.08±0.25 | 3.05±0.25 | 0.76±0.25 |

YI160808 Series

| Part Number | Impedance (Ω) | Test Freq. (MHz) | DCR Max. (Ω) | Rated Current Max. (mA) |

|---|---|---|---|---|

| YI160808U100-3R0T | 10±25% | 100 | 0.03 | 3000 |

| YI160808U100-5R0T | 10±25% | 100 | 0.01 | 5000 |

| YI160808U300-3R0T | 30±25% | 100 | 0.03 | 3000 |

| YI160808U300-5R0T | 30±25% | 100 | 0.02 | 5000 |

| YI160808U600-3R0T | 60 ±25% | 100 | 0.04 | 3000 |

YI160808 Series

| Part Number | Impedance (Ω) | Test Freq. (MHz) | DCR Max. (Ω) | Rated Current Max. (mA) |

|---|---|---|---|---|

| YI160808Z101-3R0T | 100 ±25% | 100 | 0.03 | 3000 |

| YI160808U121-2R5T | 120 ±25% | 100 | 0.10 | 2500 |

| YI160808U121-3R0T | 120 ±25% | 100 | 0.05 | 3000 |

| YI160808U181-2R0T | 180 ±25% | 100 | 0.15 | 2000 |

| YI160808U221-2R0T | 220 ±25% | 100 | 0.15 | 2000 |

| YI160808U301-2R0T | 300±25% | 100 | 0.10 | 2000 |

| YI160808U601-1R0T | 600±25% | 100 | 0.20 | 1000 |

| YI160808U601-2R0T | 600±25% | 100 | 0.10 | 2000 |

| YI160808MU102-0R8T | 1000 ±25% | 100 | 0.450 | 800 |

YI201209 Series

| Part Number | Impedance (Ω) | Test Freq. (MHz) | DCR Max. (Ω) | Rated Current Max. (mA) |

|---|---|---|---|---|

| YI201209B070-3R0T | 7±25% | 100 | 0.03 | 3000 |

| YI201209B070-6R0T | 7±25% | 100 | 0.01 | 6000 |

| YI201209U110-6R0T | 11±25% | 100 | 0.01 | 6000 |

| YI201209U220-6R0T | 22±25% | 100 | 0.025 | 6000 |

| YI201209A300-10R0T | 30±25% | 100 | 0.003 | 10000 |

| YI201209U400-3R0T | 30±25% | 100 | 0.05 | 3000 |

| YI201209U600-1R0T | 60±25% | 100 | 0.10 | 1000 |

| YI201209Z600-6R0T | 60±25% | 100 | 0.02 | 6000 |

| YI201209U800-3R0T | 80 ±25% | 100 | 0.01 | 3000 |

| YI201209U800-6R0T | 80 ±25% | 100 | 0.01 | 6000 |

| YI201209U101-3R0T | 100 ±25% | 100 | 0.06 | 3000 |

| YI201209U101-6R0T | 100 ±25% | 100 | 0.02 | 6000 |

| YI201209U121-2R0T | 120 ±25% | 100 | 0.1 | 2000 |

YI201209 Series

| Part Number | Impedance (Ω) | Test Freq. (MHz) | DCR Max. (Ω) | Rated Current Max. (mA) |

|---|---|---|---|---|

| YI201209U121-2R5T | 120 ±25% | 100 | 0.04 | 2500 |

| YI201209U121-4R0T | 120 ±25% | 100 | 0.05 | 4000 |

| YI201209U121-5R0T | 120 ±25% | 100 | 0.03 | 5000 |

| YI201209U201-4R0T | 200 ±25% | 100 | 0.035 | 4000 |

| YI201209U221-3R0T | 220 ±25% | 100 | 0.03 | 3000 |

| YI201209U301-2R0T | 300 ±25% | 100 | 0.01 | 2000 |

| YI201209U301-3R0T | 300 ±25% | 100 | 0.05 | 3000 |

| YI201209U601-2R0T | 600 ±25% | 100 | 0.15 | 2000 |

| YI201209U601-2R5T | 600 ±25% | 100 | 0.10 | 2500 |

| YI201209U471-3R0T | 470 ±25% | 100 | 0.055 | 3000 |

| YI201209Z102-1R5T | 1500 ±25% | 100 | 0.12 | 1500 |

| YI201209U152-1R0T | 1500 ±25% | 100 | 0.30 | 1000 |

YI321611 Series

| Part Number | Impedance (Ω) | Test Freq. (MHz) | DCR Max. (Ω) | Rated Current Max. (mA) |

|---|---|---|---|---|

| YI321611B100-6R0T | 10 ±25% | 100 | 0.015 | 6000 |

| YI321611B190-6R0T | 19 ±25% | 100 | 0.015 | 6000 |

| YI321611U260-6R0T | 26 ±25% | 100 | 0.010 | 6000 |

| YI321611U300-6R0T | 30±25% | 100 | 0.010 | 6000 |

| YI321611U300-8R0T | 30±25% | 100 | 0.005 | 8000 |

| YI321611U500-3R0T | 50±25% | 100 | 0.025 | 3000 |

| YI321611A500-12R0T | 50±25% | 100 | 0.0019 | 12000 |

| YI321611U600-6R0T | 60±25% | 100 | 0.015 | 6000 |

| YI321611U800-4R0T | 80±25% | 100 | 0.030 | 4000 |

| YI321611G800-6R0T | 80±25% | 100 | 0.015 | 6000 |

| YI321611U101-4R0T | 100 ±25% | 100 | 0.03 | 4000 |

| YI321611U121-4R0T | 120 ±25% | 100 | 0.04 | 3000 |

| YI321611Z121-6R0T | 120 ±25% | 100 | 0.02 | 6000 |

| YI321611U151-4R5T | 150 ±25% | 100 | 0.02 | 4500 |

| YI321611U221-4R5T | 330 ±25% | 100 | 0.02 | 4500 |

| YI321611U221-3R0T | 330 ±25% | 100 | 0.05 | 3000 |

| YI321611U301-3R0T | 330 ±25% | 100 | 0.05 | 3000 |

| YI321611U391-3R0T | 390 ±25% | 100 | 0.05 | 3000 |

| YI321611U501-3R0T | 500 ±25% | 100 | 0.06 | 3000 |

| YI321611U601-3R0T | 600 ±25% | 100 | 0.06 | 3000 |

| YI321611A601-3R0T | 600 ±25% | 100 | 0.035 | 4000 |

| YI321611U102-2R0T | 1000 ±25% | 100 | 0.20 | 2000 |

YI322513 Series

| Part Number | Impedance (Ω) | Test Freq. (MHz) | DCR Max. (Ω) | Rated Current Max. (mA) |

|---|---|---|---|---|

| YI322513U000-5R0T | 0~15Ω | 100 | 0.05 | 5000 |

| YI322513U300-3R0T | 30 ±25% | 100 | 0.05 | 3000 |

| YI322513U300-10R0T | 30 ±25% | 100 | 0.0016 | 10000 |

| YI322513U600-4R0T | 30 ±25% | 100 | 0.03 | 4000 |

| YI322513U600-6R0T | 30 ±25% | 100 | 0.02 | 6000 |

| YI322513U151-5R0T | 30 ±25% | 100 | 0.02 | 5000 |

YI451616 Series

| Part Number | Impedance (Ω) | Test Freq. (MHz) | DCR Max. (Ω) | Rated Current Max. (mA) |

|---|---|---|---|---|

| YI451616U600-6R0T | 60 ±25% | 100 | 0.01 | 6000 |

| YI451616U750-8R0T | 75 ±25% | 100 | 0.01 | 8000 |

| YI451616U800-6R0T | 80 ±25% | 100 | 0.015 | 6000 |

| YI451616U121-6R0T | 120 ±25% | 100 | 0.02 | 6000 |

| YI451616U181-3R0T | 180 ±25% | 100 | 0.025 | 3000 |

YI453215 Series

| Part Number | Impedance (Ω) | Test Freq. (MHz) | DCR Max. (Ω) | Rated Current Max. (mA) |

|---|---|---|---|---|

| YI453215U700-8R0T | 70 ±25% | 100 | 0.010 | 8000 |

| YI453215U800-8R0T | 80 ±25% | 100 | 0.010 | 8000 |

| YI453215U101-8R0T | 100 ±25% | 100 | 0.010 | 8000 |

| YI453215U121-8R0T | 120 ±25% | 100 | 0.010 | 8000 |

| YI453215F121-8R0T | 120 ±25% | 100 | 0.006 | 9000 |

| YI453215F131-8R0T | 130 ±25% | 100 | 0.010 | 8000 |

| YI453215B881-4R0T | 880 ±25% | 100 | 0.035 | 4000 |

YI565030 Series

| Part Number | Impedance (Ω) | Test Freq. (MHz) | DCR Max. (Ω) | Rated Current Max. (mA) |

|---|---|---|---|---|

| YI565030G801-8R0T | 800 ±25% | 100 | 0.010 | 8000 |

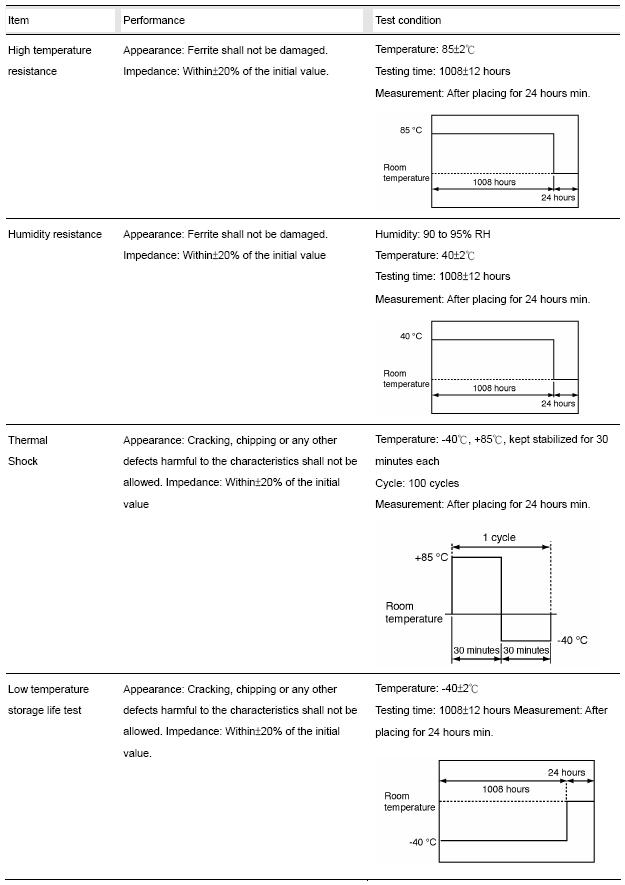

Reliability test

| No. | Items | Requirements | Test Methods and Remarks |

|---|---|---|---|

| 1 | Operating Temperature Range | -55℃~+125℃ | Includes product surface temperature rise |

| 2 | Solder ability | No mechanical damage. 95% (75% for 0603 series) or more of electrode area shall be coated by new solder. | Preheating temperature: 120℃ to 150℃ Preheating time: 60s Solder: 99.3%Sn/0.3%Ag/0.5%Cu of the Sn solder 0603 series; 200℃±5℃ Immersion depth: 1mm Duration: 3±0.5s Dip performance to a flux of about 3~5 s |

| 3 | Resistance to Soldering Heat | No mechanical damage. Inductance: Impedance change: within ±30% |

Preheating temperature: 120℃ to 150℃ Preheating time: 60s Solder: 99.3%Sn/0.3%Ag/0.5%Cu of the Sn solder 0603 series; 200℃±5℃ Immersion depth: 1mm Duration: 10±1s Dip performance to a flux of about 3~5 s |

| Adhesion of electrode | The termination and body should be no damage. | Applied force: 2N force for 0603 series;6N force for 1005 series;7N force for 1008 series;10N force for 2012, 3216 series;2012513 |

|

| Low temperature resistance | No mechanical damage. Impedance change: within ±30% |

Temperature: -55±2℃ Testing time: 1000±1h |

|

| Bending strength | No mechanical damage | Testing board: glass epoxy – resin substrate For (1±0.5) mm/s compression speed, curvature: 2mm; Hold time202513 |

|

| Vibration | No mechanical damage. Impedance change: within ±30% |

Amplitude: A period of 1.5mm Test time duration: 2h in each of 3 mutually perpendicular directions. Frequency range: 10Hz to 55Hz to 10Hz for 1min. |

|

| High temperature resistance | No mechanical damage. Impedance change: within ±30% |

Temperature: 125±2℃ Testing time: 1000±1h |

|

| Static Humidity | No mechanical damage. Impedance change: within ±30% |

Humidity: 80% to 95% RH Temperature: 60±2℃ Testing time: 1000±1h |

|

| High temperature load | No mechanical damage. Impedance change: within ±30% |

Impose current at room Testing time: 1000±1h Temperature: 85±2℃ |

|

| Temperature Shock | No mechanical damage. Impedance change: within ±30% |

Temperature: -55℃ for 30±3min / +125℃ for 30±3min Number of cycles: 100 Note: When there are questions concerning, measurement shall be made after 24±2h of recovery under the standard condition. |

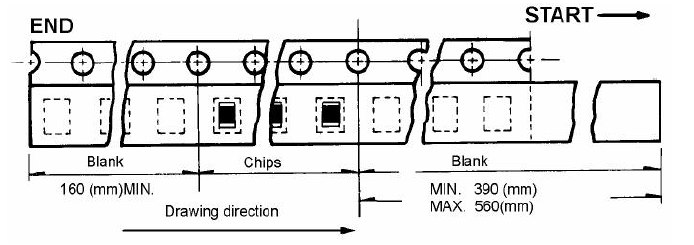

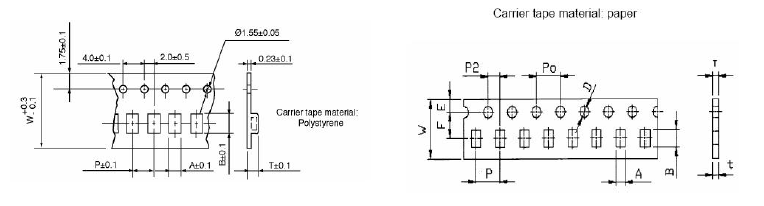

Taping Dimensions(Unit:mm) Material:Paper

Material: Paper

| TYPE | A | B | W | P | T | CHIPS/REEL |

|---|---|---|---|---|---|---|

| 100505 | 0.62 | 1.12 | 8 | 2 | 0.60 | 10000 |

| 160808 | 1.10 | 1.90 | 8 | 4 | 0.95 | 4000 |

| 201209 | 1.50 | 2.30 | 8 | 4 | 0.95 | 4000 |

Material: Polystyrene

| TYPE | A | B | W | P | T | CHIPS/REEL |

|---|---|---|---|---|---|---|

| 160808 | 1.01 | 1.80 | 8 | 4 | 1.02 | 4000 |

| 201209 | 1.42 | 2.25 | 8 | 4 | 1.04 | 4000 |

| 201212 | 1.50 | 2.35 | 8 | 4 | 1.45 | 3000 |

| 321611 | 1.88 | 3.50 | 8 | 4 | 1.27 | 3000 |

| 322513 | 2.77 | 3.42 | 8 | 4 | 1.55 | 2000 |

| 451616 | 1.93 | 4.95 | 12 | 4 | 1.93 | 2000 |

| 453215 | 3.66 | 4.95 | 12 | 8 | 1.85 | 1000 |

| YA3216M4 | 1.88 | 3.50 | 8 | 4 | 1.40 | 3000 |

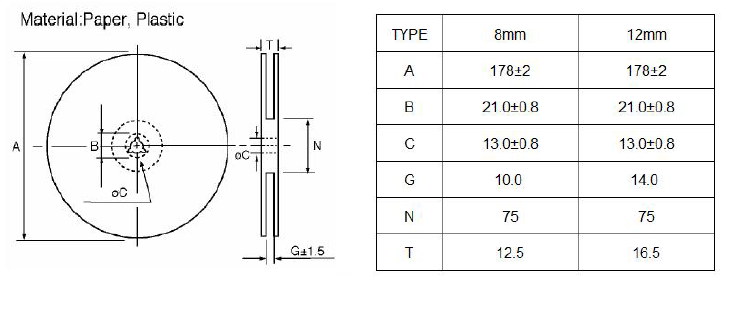

Reel Dimensions(Unit:mm)

Direction of rolling