Understanding Aluminum Electrolytic Capacitor

Introduction to Electrolytic Capacitors

- Aluminum electrolytic capacitors use a pure aluminum anode foil with an etched surface and an aluminum oxide dielectric formed by anodization – a key component in many electronic devices.

- Electrolytic capacitors offer large capacitance values, making them ideal for power supply circuits and similar applications, including smoothing and filtering. These capacitors are commonly used as filters in power supply circuits to remove unwanted AC components.

- The electrolytic capacitor market is significant, with aluminum electrolytic capacitors being a major part, and understanding their construction and characteristics is crucial for optimal use. Aluminum electrolytic capacitors were developed through advances in oxide formation and electrolyte technology.

- Aluminum electrolytic capacitors are widely used due to their low cost, wide voltage range, and good smoothing and buffering capabilities, making them a preferred choice in many applications.

- The introduction to electrolytic capacitors also involves understanding the different types, including wet (liquid electrolyte) and solid electrolyte capacitors, each with its own advantages and disadvantages. Aluminum electrolytic capacitors are sometimes called ‘wet’ or ‘solid’ types, depending on the electrolyte used.

Construction and Oxide Layer

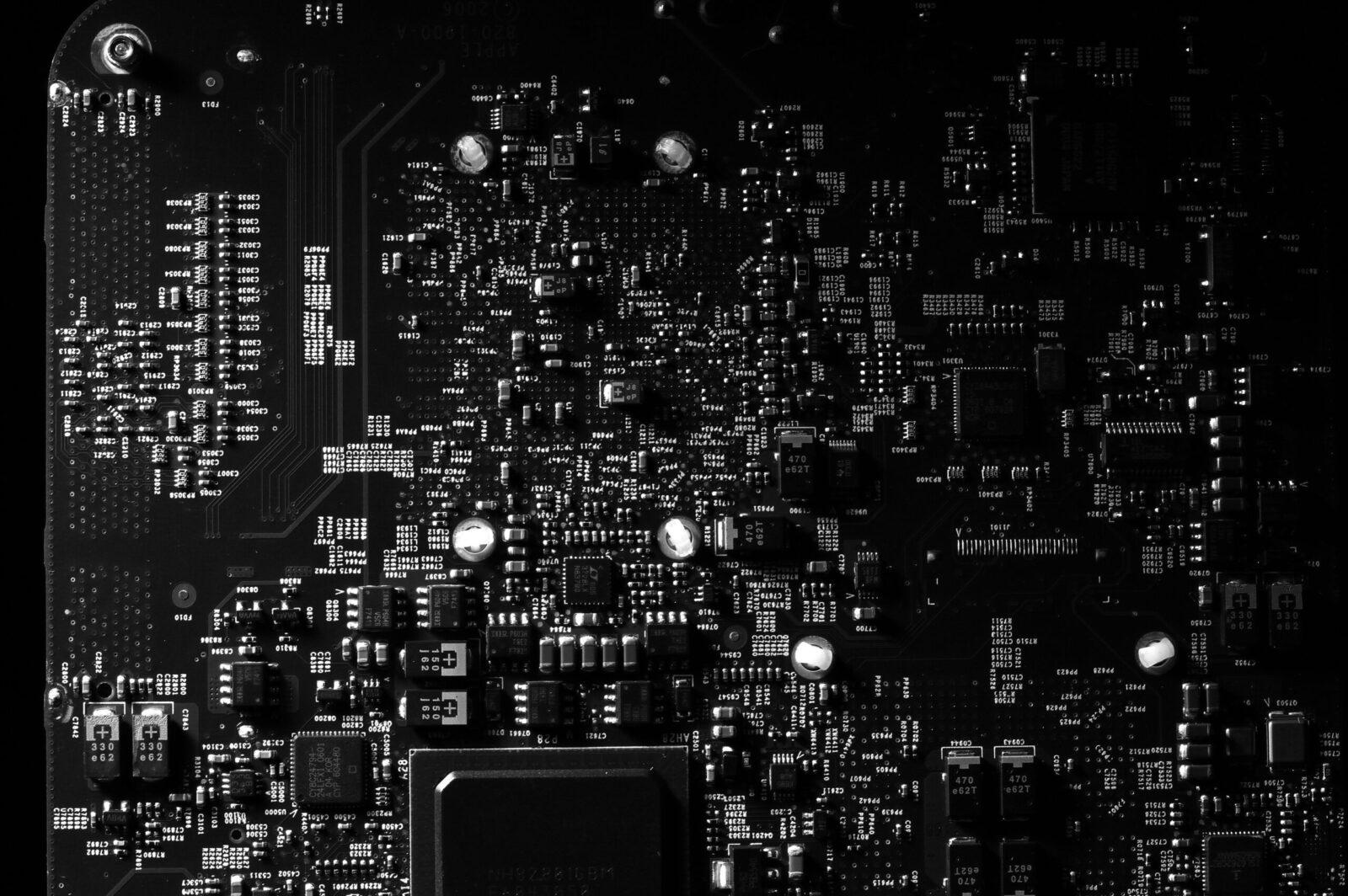

The internal structure of aluminum electrolytic capacitors consists of wound layers of aluminum foils (anode and cathode), spacers soaked in electrolyte, and a casing that maintains the arrangement and electrical contact.

The construction of aluminum electrolytic capacitors involves an aluminum oxide film as the dielectric, formed by means of a controlled electrochemical process known as forming, which increases the surface area of the aluminum foil. The cathode foil, covered with a natural oxide layer, functions as one of the two series-connected capacitors in the device, influencing overall capacitance and charge/discharge stability.

The oxide layer is crucial for the capacitor’s operation, and its formation is a key step in the manufacturing process of aluminum electrolytic capacitors.

The etching process used to roughen and enlarge the aluminum foil surface allows for a larger effective surface area, which in turn enables larger capacitance values, a critical factor in many applications.

The aluminum oxide dielectric is stable and reliable, making it suitable for a wide range of applications, including high-temperature environments.

The use of conductive polymers in some electrolytic capacitors further enhances their performance, particularly in terms of ESR (Equivalent Series Resistance).

Manufacturing Process of Aluminum Electrolytic Capacitors

- The manufacturing process of aluminum electrolytic capacitors involves several steps, including the etching of the aluminum foil to increase its surface area, and the formation of the oxide layer through anodization.

- The process also includes the application of the electrolyte, which can be either liquid (wet) or solid, depending on the type of capacitor being manufactured.

- Quality control measures are essential in the manufacturing process to ensure that the capacitors meet the required standards and specifications.

- The manufacturing process is critical in determining the characteristics and reliability of the capacitors, including their capacitance, voltage rating, and ESR. The capacitance of aluminum electrolytic capacitors is calculated using a formula that takes into account the surface area of the electrodes and the thickness of the oxide layer.

- Advances in manufacturing technology have led to improvements in the performance and reliability of aluminum electrolytic capacitors, making them even more versatile and widely used.

Types of Electrolytic Capacitors

- There are several types of electrolytic capacitors, including aluminum electrolytic capacitors, which are the most common, and tantalum electrolytic capacitors, which offer higher capacitance values but are more expensive.

- SMD (Surface Mount Device) aluminum electrolytic capacitors are specifically designed for surface mount technology, featuring a compact construction, clear polarity markings for correct orientation, and are well-suited for placement on printed circuit boards.

- The choice of capacitor type depends on the specific application, including considerations such as voltage, capacitance, and operating temperature.

- Solid electrolyte capacitors offer advantages over traditional wet electrolyte capacitors, including lower ESR and higher reliability, making them suitable for high-performance applications.

- Bipolar electrolytic capacitors are used in applications where AC voltage is present, and they offer the advantage of being able to handle both positive and negative voltages.

- The different types of electrolytic capacitors are designed to meet specific needs and applications, ranging from general-purpose use to high-reliability and high-temperature environments.

Electrical Parameters and Characteristics

- The electrical parameters of aluminum electrolytic capacitors include capacitance, voltage rating, ESR, and leakage current, all of which are critical in determining their suitability for a particular application.

- The capacitance of electrolytic capacitors is measured in microfarads (μF) and is specified as a rated or nominal value, with tolerances indicated by letter codes.

- Voltage ratings are also critical, with derated voltages specified for higher temperature ranges to maintain safety margins and prevent failure.

- ESR and dissipation factor (tan δ) are important in AC circuits, as they affect the capacitor’s performance and reliability, particularly at high frequencies.

- Understanding these electrical parameters and characteristics is essential for the proper selection and use of aluminum electrolytic capacitors in various applications.

Operating Conditions and Limitations

Aluminum electrolytic capacitors are engineered to perform reliably within defined operating conditions, particularly regarding temperature and voltage. Most aluminum electrolytic capacitors are rated for use in environments ranging from -40°C up to 125°C, with some specialized types capable of withstanding even higher temperatures. However, prolonged exposure to high temperatures can accelerate the evaporation of the electrolyte, which in turn leads to a reduction in capacitance and an increase in ESR (Equivalent Series Resistance). This degradation can significantly shorten the lifespan of the capacitor and compromise its performance in demanding applications.

Voltage is another critical parameter for electrolytic capacitors. Each capacitor is assigned a maximum voltage rating, and exceeding this limit can cause the dielectric—formed by the aluminum oxide layer—to break down, resulting in catastrophic failure. Additionally, aluminum electrolytic capacitors are polarized components, meaning they must be installed with the correct polarity. Reversing the polarity can damage the oxide layer and lead to leakage or even explosion.

Another limitation to consider is the performance of aluminum electrolytic capacitors at high frequencies. As frequency increases, the impedance of the capacitor also rises, which can diminish its effectiveness in filtering and coupling roles. Over time, the electrolyte within the capacitor may dry out, especially under high temperatures or heavy use, further increasing ESR and reducing capacitance. These factors highlight the importance of selecting the appropriate type and rating of aluminum electrolytic capacitor for each application, and of understanding the operational boundaries to ensure long-term reliability and optimal performance.

Reliability and Lifetime Considerations

- The reliability and lifetime of aluminum electrolytic capacitors depend on several factors, including the quality of the capacitor, operating conditions, and environmental factors such as temperature and humidity.

- The lifetime of non-solid aluminum electrolytic capacitors is limited by electrolyte evaporation, which is accelerated by high temperatures and can lead to a decrease in capacitance and an increase in ESR.

- Proper storage and handling are crucial to prevent damage and ensure the reliability and longevity of the capacitors, including avoiding high temperatures, moisture, and physical stress.

- The reliability of electrolytic capacitors can be estimated using the Arrhenius rule, which relates the lifetime of the capacitor to the operating temperature, allowing for the prediction of lifespan under different conditions.

- Manufacturers provide guidelines and recommendations for the use and storage of aluminum electrolytic capacitors to maximize their reliability and lifetime.

Failure Modes and Prevention

- Failure modes of aluminum electrolytic capacitors include electrolyte leakage, oxide layer breakdown, and external physical damage, all of which can be prevented or minimized with proper handling, storage, and operation.

- Preventive measures include avoiding overvoltage, high temperatures, and physical stress, as well as ensuring proper mounting and connection to prevent vibration and moisture ingress.

- Regular inspection and maintenance can help identify potential issues before they lead to failure, ensuring the reliability and longevity of the capacitors and the systems they are used in.

- Understanding the common failure modes and taking preventive measures are critical in maximizing the lifespan and performance of aluminum electrolytic capacitors.

- By following best practices and guidelines, users can minimize the risk of failure and ensure the optimal operation of their systems.

High Temperature Applications and Considerations

- High-temperature applications require special consideration when selecting aluminum electrolytic capacitors, as the operating temperature can significantly affect their reliability and lifetime.

- Capacitors designed for high-temperature applications are made with materials and constructions that can withstand these conditions, including high-temperature electrolytes and robust oxide layers.

- The choice of capacitor for high-temperature applications involves careful consideration of the specifications and characteristics, including voltage rating, capacitance, ESR, and leakage current.

- Derating the voltage and current is often necessary to ensure the reliability and longevity of the capacitors in high-temperature environments, and manufacturers provide guidelines for these conditions.

- Understanding the limitations and considerations for high-temperature applications is crucial for the proper selection and use of aluminum electrolytic capacitors in these environments.

Applications and Market for Aluminum Electrolytic

- Aluminum electrolytic capacitors are widely used in various applications, including power supplies, audio equipment, and industrial control systems, due to their high capacitance values and low cost.

- The market for aluminum electrolytic capacitors is significant, driven by demand from the electronics and industrial sectors, with applications ranging from consumer electronics to automotive and aerospace.

- The advantages of aluminum electrolytic capacitors, including their large capacitance, low cost, and wide voltage range, make them a preferred choice in many applications, from general-purpose use to high-reliability environments.

- The development of new technologies and materials is expected to further expand the applications and market for aluminum electrolytic capacitors, including the use of conductive polymers and other advanced materials.

- Understanding the applications and market trends is essential for manufacturers, suppliers, and users of aluminum electrolytic capacitors, as it helps in predicting demand, developing new products, and optimizing supply chains.

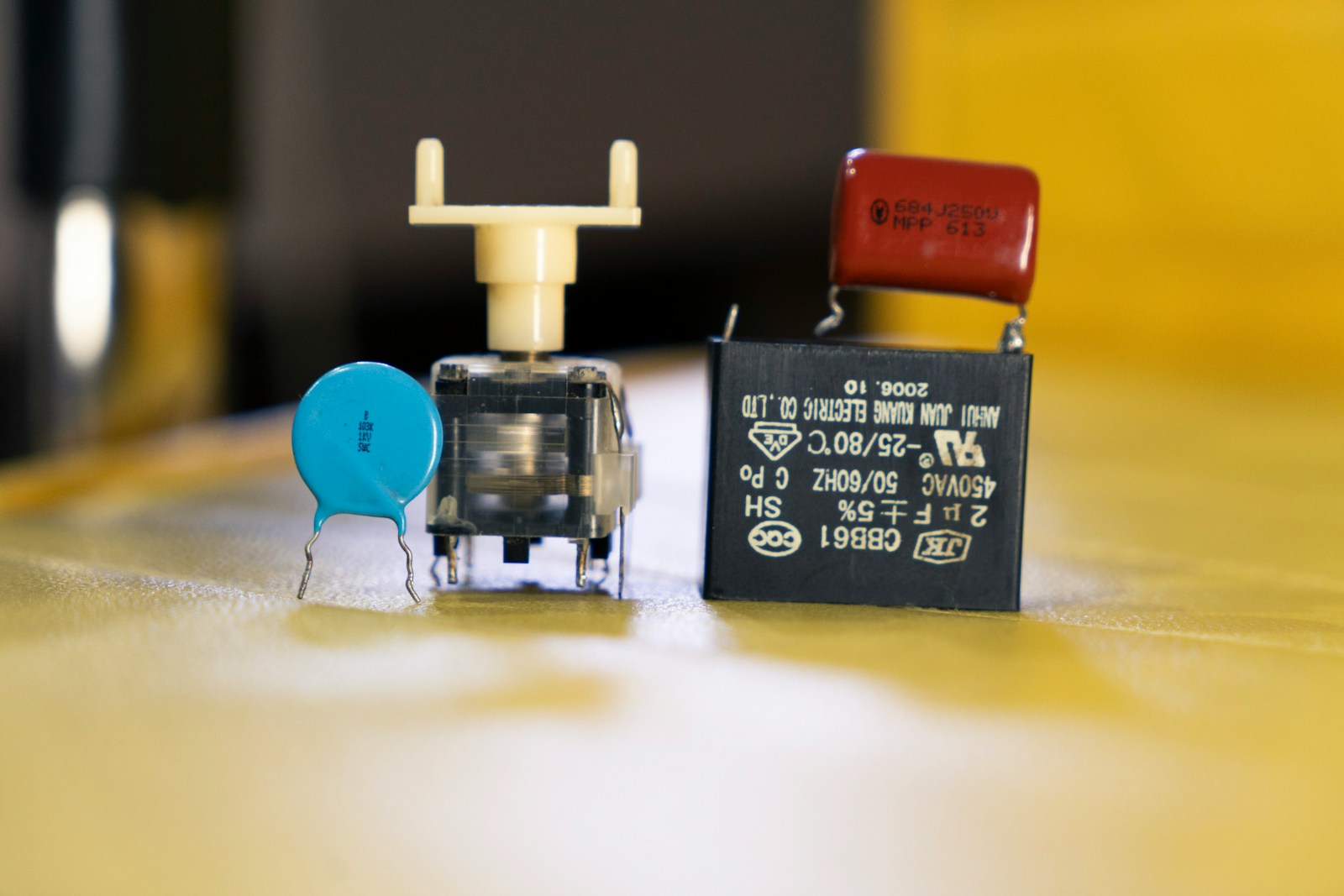

- Pictures or diagrams are often used to illustrate the various types, constructions, and physical appearances of aluminum electrolytic capacitors.

Advantages and Disadvantages of Capacitor Use

- The advantages of using aluminum electrolytic capacitors include their high capacitance values, low cost, and wide voltage range, making them suitable for a wide range of applications.

- However, they also have disadvantages, such as limited lifetime due to electrolyte evaporation, polarity sensitivity, and larger size compared to other capacitor types.

- The choice of capacitor type depends on the specific application and requirements, including considerations such as voltage, capacitance, operating temperature, and reliability.

- Understanding the advantages and disadvantages of aluminum electrolytic capacitors is crucial for the proper selection and use of these components in various applications.

- By weighing the pros and cons, designers and engineers can make informed decisions about the use of aluminum electrolytic capacitors in their systems and products.

Capacitor Behavior and Storage

- The behavior of aluminum electrolytic capacitors during storage and disuse is critical, as improper storage can lead to degradation and reduced lifespan.

- Capacitors should be stored in a cool, dry place, away from direct sunlight and moisture, and should not be exposed to high temperatures or physical stress.

- Preconditioning (applying voltage via a resistor) can restore oxide layers in older capacitors but is generally unnecessary for modern types, which are designed to withstand storage and disuse.

- Understanding the behavior of capacitors during storage and disuse is essential for maintaining their reliability and longevity, and for ensuring that they perform as expected when put into service.

- Proper storage and handling practices can help prevent damage and ensure the optimal performance of aluminum electrolytic capacitors.

Design and Implementation Considerations

When incorporating aluminum electrolytic capacitors into electronic designs, careful consideration of several key factors is essential to achieve the desired performance and reliability. One of the first decisions involves choosing between a liquid electrolyte and a solid electrolyte. Solid electrolyte capacitors, while typically more expensive, offer lower ESR and greater reliability, making them suitable for high-performance or mission-critical applications. In contrast, liquid electrolyte types are often favored for their cost-effectiveness in general-purpose circuits.

The etching process applied to the aluminum foil is another crucial aspect, as it increases the surface area available for the formation of the oxide layer, directly impacting the capacitance of the finished product. The manufacturing process, including the precise formation of the oxide layer and the selection of high-quality materials, determines important characteristics such as capacitance value, voltage rating, and leakage current.

During the implementation phase, it is vital to select aluminum electrolytic capacitors with appropriate voltage ratings and capacitance values for the intended application. For tasks such as smoothing and filtering, capacitors with higher capacitance and low ESR are preferred to ensure stable operation. Observing the correct polarity during installation is essential to prevent damage, and in circuits where polarity may reverse, bipolar or non-polar electrolytic capacitors should be considered.

Attention should also be given to mounting and soldering techniques, as improper handling can introduce mechanical stress, potentially leading to premature failure. By thoroughly evaluating these design and implementation considerations, engineers can maximize the benefits of aluminum electrolytic capacitors, ensuring reliable performance across a wide range of electronic devices, from power supplies and audio systems to industrial and automotive electronics.

Parallel Connection and Capacitor Configuration

- Connecting aluminum electrolytic capacitors in parallel can increase the total capacitance and improve the reliability of the system, but requires careful consideration of the voltage and current ratings.

- The configuration of capacitors in parallel or series depends on the specific application and requirements, including considerations such as voltage, capacitance, and operating temperature.

- Proper connection and configuration of capacitors are critical to ensure the reliability and performance of the system, and to prevent overheating, vibration, or other forms of stress.

- Understanding the principles of parallel and series connections is essential for the proper design and operation of systems using aluminum electrolytic capacitors.

- By following best practices and guidelines, designers and engineers can ensure the optimal performance and reliability of their systems.

Conclusion and Future Directions

- Aluminum electrolytic capacitors are a crucial component in many electronic devices and systems, offering high capacitance values, low cost, and wide voltage range.

- Understanding their construction, characteristics, and applications is essential for the proper selection and use of these components.

- Future developments in materials and technologies are expected to further improve the performance, reliability, and lifespan of aluminum electrolytic capacitors, expanding their applications and market.

- The importance of proper storage, handling, and operation cannot be overstated, as it directly affects the reliability and longevity of the capacitors and the systems they are used in.

- As technology continues to evolve, the role of aluminum electrolytic capacitors will remain critical, and ongoing research and development will be necessary to meet the changing needs of the electronics and industrial sectors.

| Section | Description / Key Points |

|---|---|

| Introduction to Electrolytic Capacitors | Aluminum electrolytic capacitors use pure aluminum anode foil and aluminum oxide dielectric. Offer large capacitance, ideal for power supply circuits, smoothing, and filtering. Available in wet (liquid) and solid electrolyte types. Widely used due to low cost, wide voltage range, and buffering capabilities. |

| Construction and Oxide Layer | Wound layers of aluminum foils (anode/cathode) with spacers soaked in electrolyte. Aluminum oxide film formed by anodization increases surface area. Etching enlarges surface area for higher capacitance. Conductive polymers improve ESR. Oxide layer and construction critical for stability and reliability. |

| Manufacturing Process | Etching of aluminum foil, anodization to form oxide layer, application of electrolyte (liquid or solid), quality control. Process affects capacitance, voltage rating, ESR, and reliability. Advances improve performance and versatility. |

| Types of Electrolytic Capacitors | Aluminum electrolytic, tantalum electrolytic, SMD aluminum electrolytic, solid electrolyte, bipolar types. Selection depends on voltage, capacitance, temperature, and application. Solid types: lower ESR, higher reliability. Bipolar: AC applications. |

| Electrical Parameters and Characteristics | Capacitance (μF), voltage rating, ESR, leakage current. Cutoff, tolerance, and dissipation factor (tan δ) important for AC performance. Proper understanding critical for selection. |

| Operating Conditions and Limitations | Temperature range: -40°C to 125°C (higher for specialized types). High temperature accelerates electrolyte evaporation → increased ESR, reduced capacitance. Voltage: exceed rating → dielectric breakdown. Polarized components require correct polarity. High-frequency performance decreases with frequency. |

| Reliability and Lifetime Considerations | Lifetime affected by temperature, humidity, and electrolyte evaporation. Storage and handling critical. Arrhenius rule used for lifetime estimation. Manufacturers provide guidelines for optimal reliability. |

| Failure Modes and Prevention | Electrolyte leakage, oxide breakdown, physical damage. Prevent by avoiding overvoltage, high temperatures, mechanical stress; proper mounting; regular inspection. |

| High Temperature Applications | High-temp capacitors use robust materials and high-temp electrolytes. Voltage/capacitance derating often necessary. Selection requires attention to ESR, leakage, and overall reliability. |

| Applications and Market | Widely used in power supplies, audio, industrial control, consumer electronics, automotive, aerospace. Large market due to cost-effectiveness and versatility. New technologies (conductive polymers) expand performance. |

| Advantages and Disadvantages | Advantages: high capacitance, low cost, wide voltage range. Disadvantages: limited lifetime, polarity sensitivity, larger size. Proper selection essential for optimal application. |

| Capacitor Behavior and Storage | Store in cool, dry, low-stress environment. Preconditioning may restore older types. Proper storage ensures reliability and longevity. |

| Design and Implementation Considerations | Choose liquid vs. solid electrolytes, consider etching and oxide layer formation, voltage and capacitance selection, polarity, mounting/soldering practices. Ensure ESR and performance suitable for application. |

| Parallel Connection and Capacitor Configuration | Parallel increases total capacitance, requires careful consideration of voltage/current ratings. Configuration impacts reliability and performance. Correct design ensures system stability. |

| Conclusion and Future Directions | Aluminum electrolytic capacitors: high capacitance, low cost, wide voltage. Proper understanding critical for use. Future improvements in materials and technology expected to enhance performance, reliability, and lifespan. Proper storage, handling, and operation remain essential. |