Essential Guide to Wet Tantalum Capacitors: Benefits and Applications

Introduction to Wet Tantalum Capacitors with Higher Capacitance

- Wet tantalum capacitors offer higher energy density and operate at voltages up to 630 V, making them a suitable solution for high-performance applications – for example, in military and aerospace products and space systems. Wet tantalum capacitors are commonly available in axial configurations, which are preferred for certain high-reliability applications.

- They use liquid or gelled sulfuric acid electrolyte with self-healing properties and are valued for their low leakage current for thin dielectric layers, providing a reliable component for demanding environments.

- In accordance with their high-reliability requirements, wet tantalum capacitors are manufactured with high-purity materials and are hermetically sealed to prevent contamination.

- The connection of wet tantalum capacitors requires careful consideration to ensure safe and reliable operation, and blocked or reversed connections can cause catastrophic failure.

- Learn more about the benefits and applications of wet tantalum capacitors in this essential guide, and discover how they can provide a high-capacitance solution for your product.

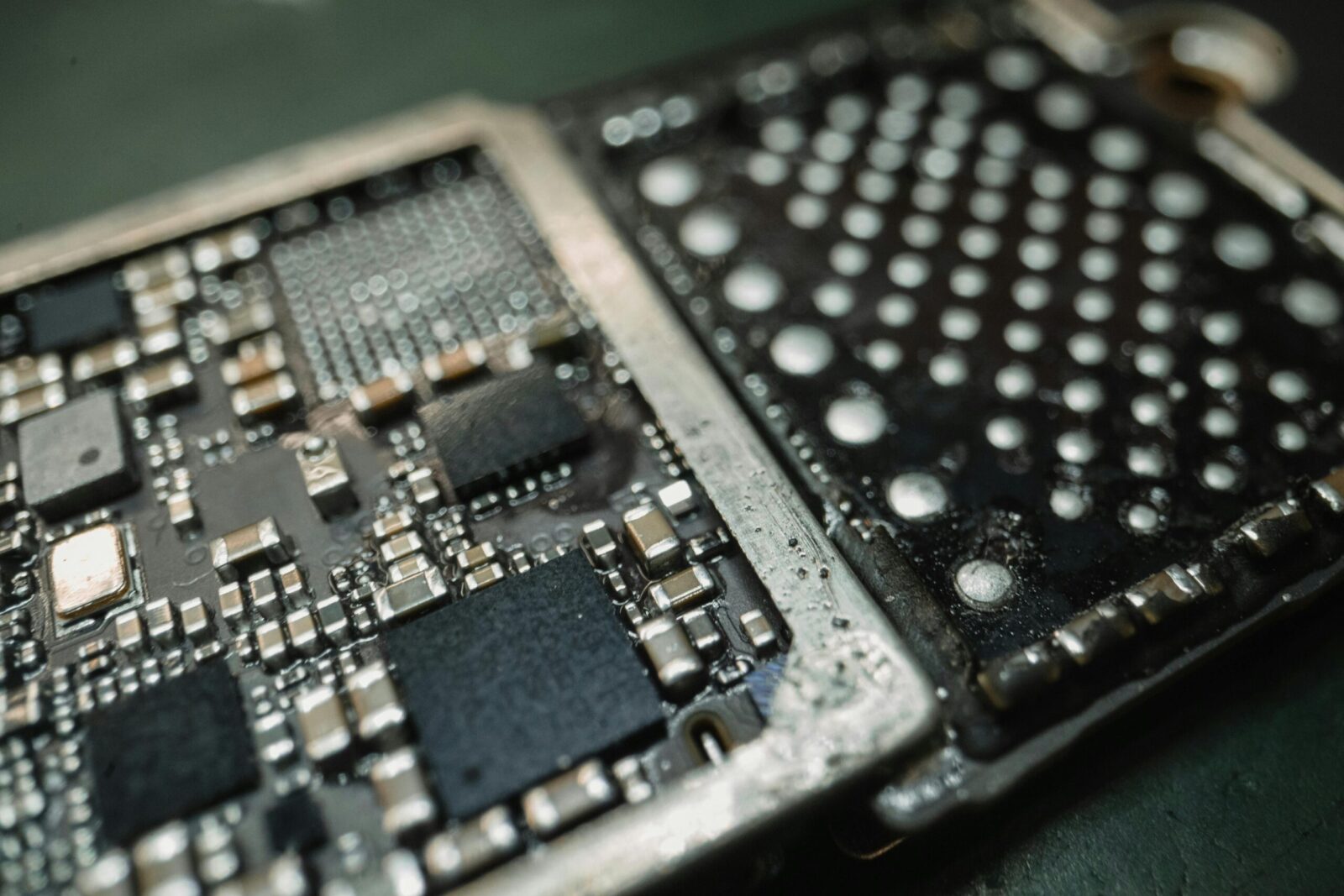

Hermetically Sealed Construction and Materials

- Wet tantalum capacitors are constructed from high-purity tantalum powder, which is compressed and sintered to form the anode, resulting in higher capacitance per volume.

- The dielectric is a tantalum pentoxide oxide layer formed on the pellet surface, providing a high-temperature stable and reliable component.

- A liquid or gelled sulfuric acid electrolyte acts as the cathode, allowing for self-healing properties and high energy density, making them a suitable choice for military and mil-spec applications.

- The materials used in wet tantalum capacitors are carefully selected to ensure high reliability and long lifetime, even in harsh environments, and are provided with a high level of quality control.

- The result is a high-performance component that can operate in a wide range of temperatures and conditions, making it a versatile solution for various applications.

Operating Conditions

Tantalum capacitors are engineered to deliver reliable performance when operated within their specified temperature and voltage limits. For example, solid tantalum capacitors are commonly rated for temperatures ranging from -55°C up to 125°C, with certain military and mil-spec components manufactured to withstand even higher temperature extremes. In accordance with stringent MIL standards, these capacitors are designed to maintain stable electrical characteristics and ensure a dependable connection, even in the most demanding environments.

To achieve higher capacitance and long-term reliability, many tantalum capacitors are hermetically sealed. This construction protects the component from moisture and contaminants, which is especially critical in military, aerospace, and other high-temperature applications. The hermetically sealed design not only preserves the integrity of the capacitor but also reduces the risk of electrical shorts and other failures that could compromise the product.

However, it is important to consider the impact of blocked or restricted airflow around the capacitor. Inadequate cooling can lead to overheating, which may result in diminished performance or, in severe cases, component failure. For instance, a product intended for use in a high-temperature environment—such as avionics or defense systems—may require a tantalum capacitor with a higher voltage rating and robust construction to ensure reliable operation throughout its service life.

Selecting the right solution involves understanding the specific operating conditions of the application and choosing a component that meets those requirements. By learning about the voltage, temperature, and expected lifespan of the system, engineers can make informed decisions and optimize the overall performance of their design.

The result of careful component selection and adherence to recommended operating conditions is a reliable, efficient system that performs as intended, even under challenging circumstances. Provided that these factors are taken into account, tantalum capacitors can be a critical enabler for high-performance, mission-critical products across a wide range of industries.

Common Applications and Industries

Wet tantalum capacitors are widely used in industries and applications that demand high reliability, stability, and performance under challenging conditions. Their high capacitance, low leakage current, and ability to operate at high temperatures make them ideal for military and aerospace systems, where durability and consistent operation are critical.

In addition to military and aerospace, wet tantalum capacitors find applications in medical equipment, telecommunications, industrial controls, and power supply systems. These capacitors support functions such as filtering, energy storage, and voltage smoothing in devices that require long service life and dependable performance.

Due to their hermetically sealed construction, wet tantalum capacitors are also suitable for harsh environments, including oil exploration probes and other rugged industrial applications. Their self-healing electrolyte properties further enhance reliability, reducing maintenance needs and downtime.

Overall, wet tantalum capacitors provide a versatile and robust solution for a variety of high-performance electronic components across multiple industries.

Future Trends

As technology continues to evolve, wet tantalum capacitors are expected to advance in several key areas to meet the growing demands of modern electronic systems. Innovations in materials and manufacturing processes aim to improve capacitance density, reduce size, and enhance reliability even further.

One significant trend is the development of improved electrolytes and dielectric materials that allow for higher voltage ratings and better temperature stability, expanding the range of applications for wet tantalum capacitors. Additionally, efforts to reduce environmental impact and reliance on conflict minerals are driving research into more sustainable sourcing and production methods.

Integration with smart monitoring technologies is another emerging trend, enabling real-time health diagnostics and predictive maintenance for critical components in aerospace, military, and industrial systems. This proactive approach can significantly reduce downtime and improve system safety.

Overall, wet tantalum capacitors will continue to play a vital role in high-performance electronics, adapting to the challenges of miniaturization, higher power densities, and stringent reliability requirements in the years ahead.

| Section | Description / Key Points |

|---|---|

| Introduction to Wet Tantalum Capacitors | Offer high energy density, operate up to 630 V. Suitable for high-performance applications like military, aerospace, and space systems. Axial configurations common. Use liquid/gelled sulfuric acid electrolyte with self-healing properties and low leakage current. Hermetically sealed for high reliability. |

| Hermetically Sealed Construction and Materials | Made from high-purity tantalum powder (anode). Dielectric: tantalum pentoxide layer for high-temperature stability. Electrolyte: liquid or gelled sulfuric acid. Materials selected for high reliability and long lifetime. Operates in wide temperature ranges and harsh conditions. |

| Operating Conditions | Designed for reliable performance within specified voltage and temperature limits (-55°C to 125°C or higher for mil-spec). Hermetic sealing prevents moisture/contamination, reduces risk of shorts. Cooling/airflow considerations important to avoid overheating. Proper selection ensures high performance and reliability. |

| Common Applications and Industries | Military, aerospace, medical equipment, telecommunications, industrial controls, power supplies. Functions: filtering, energy storage, voltage smoothing. Suitable for harsh environments (e.g., oil exploration). Self-healing electrolytes reduce maintenance and downtime. |

| Future Trends | Advances in materials and manufacturing improve capacitance density, reduce size, enhance reliability. Improved electrolytes and dielectrics allow higher voltage and temperature stability. Trends include sustainable sourcing, reduced environmental impact, and integration with smart monitoring technologies for predictive maintenance. |

| Key Benefits | High capacitance and energy density, low leakage current, high reliability in demanding environments, long service life, self-healing properties, hermetically sealed construction, suitable for high-temperature and rugged applications. |